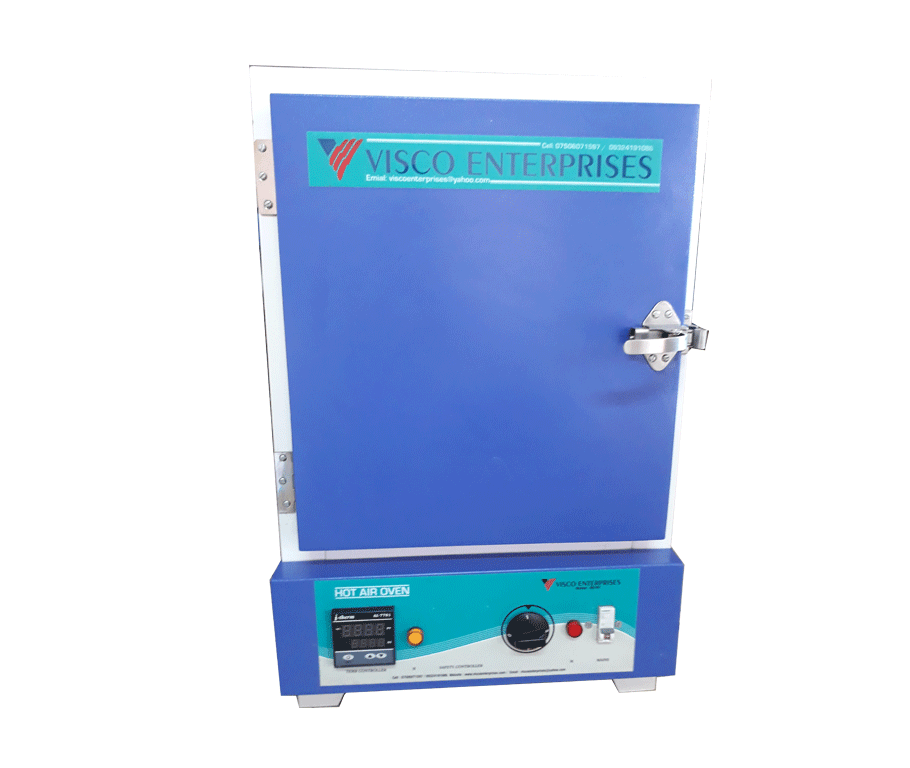

Oven

Introduction :

Introduction :

"VISCO" make Laboratory Ovens are designed and fabricated to suit various I.S. & A.S.T.M. standards application in the growing field of Medical, Agricultural, Industrial, Research laboratories & Hospitals.

Features :

a) Temperature up to 250C.

b) Microprocessor based PID Controller with an accuracy

of +/-10C

Chamber Volume |

27ltrs. |

43 ltrs. |

91 ltrs. |

121 ltrs. |

216 ltrs. |

324 ltrs. |

|

Internal Size |

30 X 30 X30 |

35 X 35 X35 |

45 X 45 X45 |

45 X 45 X 60 |

60 X 60 X 60 |

60 X 60 X90 |

|

External Size (lwh) |

41 X 43 X62 |

46 X 48 X67 |

56 X 58 X77 |

56 X 58 X 94 |

71 X 73 X 94 |

71X73 X125 |

|

Accuracy |

+ / -10C |

||||||

Uniformity |

+ / 1% of set value |

||||||

Heat up time |

45 min. upto 2500C w |

||||||

Controller |

Microprocessor based PID Controller |

||||||

Sensor |

J - type |

||||||

Internal Chamber |

Stainless Steel 304 quality |

||||||

External |

Mild Steel Powder Coated |

||||||

Shelves |

G.I. / Stainless Steel Wire Mesh. |

||||||

Insulation |

Glass Wool 65 mm. |

||||||

Ventilator |

Adjustable type (Aluminium) |

||||||

Door Gasket |

High Temp. Felt / Asbestos Gasket |

||||||

Door |

Inner |

Mild Steel / Stainess Steel 304 quality. |

|||||

Outer |

Mild Steel |

||||||

Optional |

|||||||

Safety device |

Digital Controller For Over Heating Cut Off Or Alaram |

||||||

Timer |

ON / OFF cycle |

||||||

Door Gasket |

Silicon Rubber Gasket |

||||||

Air Circulation |

Forced air circulation from Top or Bottom |

||||||

Electronic requirements AC 230V & 50 Hz cycle333 |

|||||||

|

|

|

|

|